| About Us | Contact Us | Language Choose: |

|

| About Us | Contact Us | Language Choose: |

|

Keywords: Angular contact ball bearings, Self-aligning ball bearings, Self-aligning roller bearing, Thrust self-aligning roller bearing, Tapered roller bearing, Deep groove ball bearings, Thrust ball bearing, Thrust roller bearing, Cylindrical roller bearing, Four point contact ball bearing, Thrust cylindrical roller bearing, Spherical ball bearing with seat, Thrust tapered roller bearing

Bearing is an important part of mechanical equipment. Its main function is to support the mechanical rotating body to reduce the mechanical load friction coefficient of the equipment in the transmission process.

According to the bearing direction or nominal contact Angle, bearings are divided into centripetal bearings and thrust bearings.

According to the type of rolling body, it is divided into: ball bearing, roller bearing.

According to whether it can be self-aligning, it is divided into: self-aligning bearing, non-self-aligning bearing (rigid bearing).

According to the number of rolling body, it is divided into: single row bearing, double row bearing, multi row bearing.

According to whether the parts can be separated, it is divided into separable bearing and non-separable bearing.

In addition, there are classifications by structure shape and size.

This article mainly shares the characteristics, differences and corresponding uses of 14 common bearings.

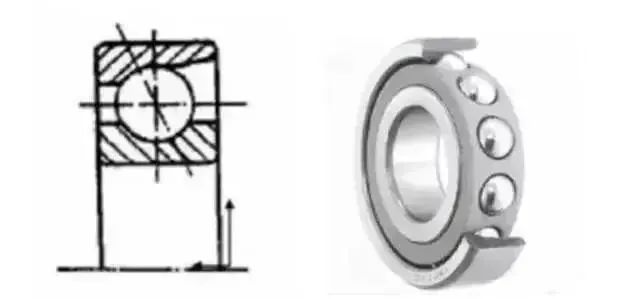

There is a contact Angle between the ring and the ball. The standard contact Angle is 15°, 30° and 40°. The larger the contact Angle is, the greater the axial load capacity will be, and the smaller the contact Angle is, the more conducive to high-speed rotation. Structurally, two single-row angular contact ball bearings combined on the back share inner ring and outer ring, which can withstand radial load and two-way axial load.

Angular contact ball bearings main uses:

Single row: machine tool spindle, high frequency motor, gas turbine, centrifuge, small car front wheel, differential pinion shaft.

Double column: oil pump, Roots blower, air compressor, all kinds of transmission, fuel injection pump, printing machinery.

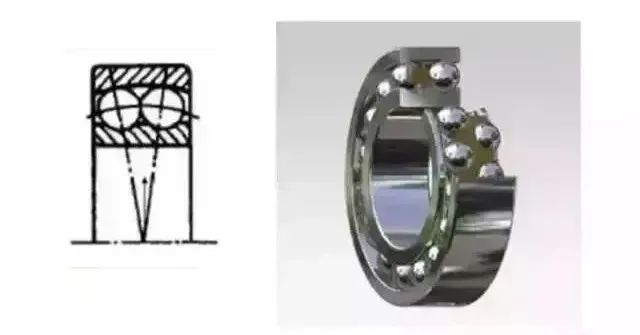

Self-aligning ball bearings

Double row of steel balls, the outer ring raceway is the inner spherical type, so it can automatically adjust the shaft or shell bending or different heart caused by the wrong axis, taper hole bearing can be conveniently installed on the shaft through the use of fasteners, mainly bear radial load.

Self-aligning ball bearings

Main applications: woodworking machinery, textile machinery transmission shaft, vertical belt seat self-aligning bearing.

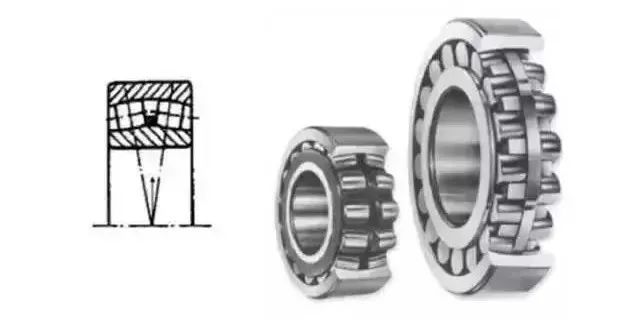

In these bearings are of spherical raceway outer ring and double groove between the inner ring is equipped with spherical roller, according to the different internal structure, divided into R, RH, RHA and SR four type, because of outer ring raceway arc center and bearing center consistent, with self-aligning performance, thus can be automatically adjusted because of the shaft or shell buckling or axis deviation caused by different heart, Can withstand radial load and two-way axial load.

Main uses of self-aligning roller bearings:

Paper making machinery, reducer, railway vehicle axle, rolling mill gear box seat, rolling mill roller table, crusher, vibrating screen, printing machinery, woodworking machinery, all kinds of industrial reducer, vertical belt seat self-aligning bearing

Thrust self-aligning roller bearing

The spherical roller in this type of bearing is inclined, because the raceway surface of the seat ring is spherical, with self-aligning performance, so the shaft can be allowed to have a number of incline, the axial load capacity is very large, and the axial load can also withstand a number of radial load, generally using oil lubrication.

Thrust self-aligning roller bearing main uses:

Hydraulic generator, vertical motor, propeller shaft for ship, reducer for rolling screw of rolling mill, tower crane, coal mill, extruder, forming machine.

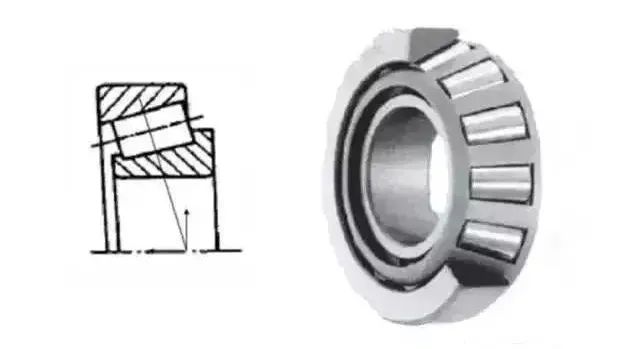

This type of bearing is equipped with a round table roller, the roller is guided by the big barrier of the inner ring, the design makes the inner ring raceway surface, the outer ring raceway surface and the cone surface of the roller rolling surface intersect at a point on the center line of the bearing. Single row bearing can withstand radial load and unidirectional axial load, double row bearing can withstand radial load and bidirectional axial load, suitable for heavy load and impact load.

Tapered roller bearings main uses:

Automobile: front wheel, rear wheel, transmission, differential pinion shaft. Spindle of machine tool, construction machinery, large agricultural machinery, gear reducer of railway rolling stock, roller neck of rolling mill and reducer.

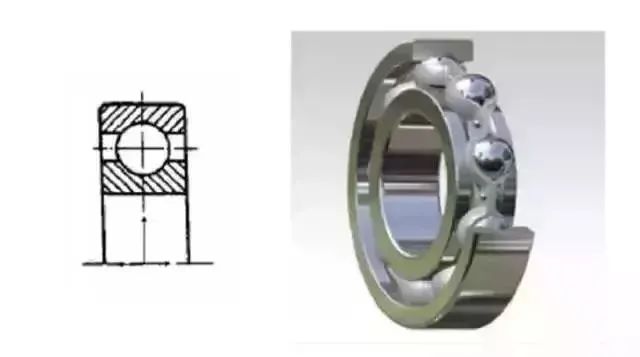

In structure, each ring of deep groove ball bearing has a continuous groove type raceway whose cross section is about one third of the equatorial circumference of the ball. Deep groove ball bearings are mainly used to bear radial load, but also can bear a certain axial load.

When the radial clearance of the bearing increases, it has the property of angular contact ball bearing, which can withstand the alternating axial load in two directions. Compared with other types of bearings of the same size, this type of bearing has small friction coefficient, high limit speed and high accuracy, and is the preferred type of bearing for user selection.

Deep groove ball bearings main uses:

Automobile, tractor, machine tool, motor, water pump, agricultural machinery, textile machinery, etc.

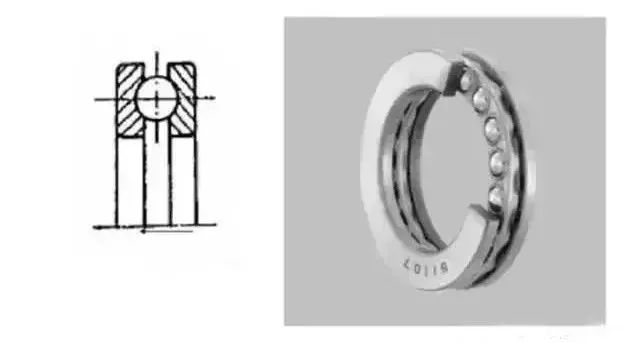

Thrust ball bearing

The raceway is composed of a gasket raceway ring with a ball and a cage assembly, and the raceway ring with the shaft is called the shaft ring, and the raceway ring with the shell is called the seat ring. Bidirectional bearing will be the middle ring shaft, unidirectional bearing can withstand unidirectional axial load, bidirectional bearing can withstand bidirectional axial load (neither can withstand radial load).

Thrust ball bearing main uses: automobile steering pin, machine tool spindle.

Thrust roller bearing

The thrust roller bearing is used to bear the axial load of the main shaft, the longitudinal combined load, but the longitudinal load shall not exceed 55% of the axial load. Compared with other thrust roller bearings, this kind of bearing has lower friction coefficient, higher speed and self-aligning ability. The roller of type 29000 bearing is an asymmetric spherical roller, which can reduce the relative sliding of the rod and raceway in the work, and the roller is long and has a large diameter, and the number of rollers is large and the load capacity is large. It is usually lubrized by oil, and the individual low speed can be lubrized by grease.

Thrust roller bearing main uses: hydraulic generator, crane hook.

The roller of cylindrical roller bearing is usually guided by the two sides of a bearing ring, and the cage roller and the guide ring form an assembly, which can be separated from another bearing ring, and belongs to the separable bearing.

This kind of bearing is more convenient to install and disassemble, especially when the inner and outer ring are required to be interference fit with the shaft and shell. This kind of bearing is generally only used to bear radial load, only the inner and outer ring with a barrier side of the single row bearing can bear smaller steady axial load or larger intermittent axial load.

Cylindrical roller bearings are mainly used for large motors, machine tool spindles, axle boxes, diesel engine crankshafts, automobiles, transformer boxes, etc.

Four point contact ball bearing

Can bear radial load and axial load, two-way single bearing can be combined to replace the front or on the back of the combination of angular contact ball bearing, applies to pure axial load or under axial load component larger synthetic load, the bearing any direction of axial load can form one of the contact Angle, so the ring with the ball always sitting a double-dealing under point contact line.

Four point contact ball bearings: aircraft jet engines, gas turbines.

Thrust cylindrical roller bearing

It is composed of gasket shaped raceway ring (shaft ring, seat ring) and cylindrical roller and cage assembly. Cylindrical roller is processed by convex surface, so the pressure distribution between roller and raceway surface is uniform, can withstand unidirectional axial load, axial load capacity is large, axial rigidity is also strong.

Thrust cylindrical roller bearing main uses: oil drilling machine, making iron and steel machinery.

Thrust needle roller bearing

The separation type bearing is composed of raceway ring, needle roller and cage assembly, which can be combined with thin raceway ring processed by stamping or thick raceway ring processed by cutting. Non-separation type bearing is composed of precision stamping raceway ring and needle roller and cage components of the integral type bearing, can withstand unidirectional axial load, this type of bearing space is small, is beneficial to the compact design of machinery, most of the use of only needle roller and cage components, and the mounting surface of the shaft and shell as raceway surface.

Thrust needle roller bearing main uses: automobile, cultivator, machine tool and other speed change device.

Thrust tapered roller bearing

This kind of bearing with a frustum of a cone shape roller (big end for spherical), roller by race lap, lap (axis) guard accurate guidance, design makes the axial ring and seat on the surface of the raceway surface and on the surface of the roller rolling cone vertex meet in bearing center line, one-way bearings can withstand axial load one-way, two-way bearing can be subject to bi-directional load.

Thrust tapered roller bearing main uses:

One way: crane hook, oil drilling rig ring.

Bidirectional: roller neck of rolling mill.

Spherical ball bearing with seat

The outer spherical ball bearing with seat consists of the outer spherical ball bearing with seal on both sides and cast (or steel plate stamped) bearing housing. The inner structure of the outer spherical ball bearing is the same as that of the deep groove ball bearing, but the inner ring of the bearing is wider than the outer ring, and the outer ring has a truncated spherical outer surface, which can be automatically self-aligning when matched with the concave sphere of the bearing seat.

Main applications: mining, metallurgy, agriculture, chemical industry, textile, printing and dyeing. Conveying machinery, etc.